Kilnside

| H I N C H L E Y W O O D | ||||||||

| E |

|

|

|

|

|

|

C | |

| S |

|

|

|

|

|

|

H | |

| H |

|

|

|

|

|

|

E | |

| E |

|

|

|

|

|

|

S | |

| R |

|

|

|

|

|

|

S | |

|

|

|

|

|

|

N | ||

| O X S H O T T | ||||||||

Planning Applications

№ 8

| ADDRESS: 8 Kilnside

|

Historical Notes

The manufacture of clay bricks and tiles was for many years Claygate's principal industry and source of employment. It is said that bricks from Claygate were used in the building of Hampton Court Palace in the 16th century, but no positive evidence to support this has yet been uncovered. But it is known that Claygate bricks were used to repair the Palace during the 19th century, and it would be fair to assume that the repairers would have wanted bricks from the same source as those used when the Palace was built.

There are distinct geological differences between the various types of clay. For example, the clay and sand beds to be found at Claygate, and in some other locations such as around Esher, at Wimbledon Common, Richmond Park, Sydenham and elsewhere, are different in character and composition from most other clay deposits in the Thames Valley. And because of the clear exposure and thickness of sedimentation of these particular clay deposits in Claygate, they were given the generic name of Claygate Beds by Dewey, the geologist, in 1912.

The oldest of the three clay pits in Claygate was located near Common Road and Stevens Lane on land now occupied by Kilnside and Fishersdene. Fishersdene took its name from the clay pond over which it was built.

In 1838 the pit was being worked by George Waffew. In 1888 this brickfield was known as Roser's Brickfield. Evidence suggests the brickfield was leased by Roser from the Speer family who acquired the Manor of Weston in 1801, and owned extensive lands in Thames Ditton and Claygate. However, the reference to Roser must have been a hangover from earlier years, as in 1874 through to the late 1890s, Thomas Dawes is recorded as working the Common Road brickfield, presumably under a lease from the Speer family. There may be a connection between Thomas Dawes and Dawes Court, a small turning off the Portsmouth Road, near Esher police station. The small wooden-fronted cottages in Dawes Court date back to the 18th century, although they have been refaced externally and renovated internally in recent years. This court also used to contain one of Esher's two blacksmith's shops.

In 1899 the brickfield was leased by Hannibal Speer of the Manor House, Thames Ditton, to Welch & Sons: Charles and his two sons Charles and Thomas. Charles senior died in May 1900 at the age of 69, while his son Charles died in 1905. Thomas lived until 1939, and his wife Rosina until 1956. All four are buried in Holy Trinity's churchyard. The Welch family lived for many years in various houses in St Leonards Road, and owned several properties in Common Road.

Hannibal Speer died a bachelor in April 1915, and his heir to this property, Marianne Litchfield-Speer, also of Manor House, Thames Ditton, leased the brickfield for 21 years from 1921 to Frederick de Bertodano, Marquis del Moral, of Belsize Square, London, and his brother, Henry de Bertodano of Walton-on-Thames. Presumably, therefore, the Welch family relinquished their interest in the brickfield in that year. During this period adjoining lands were leased or purchased from Lord Foley and Mary, Countess of Lovelace, but these were relatively minor parts of the total brickfield site.

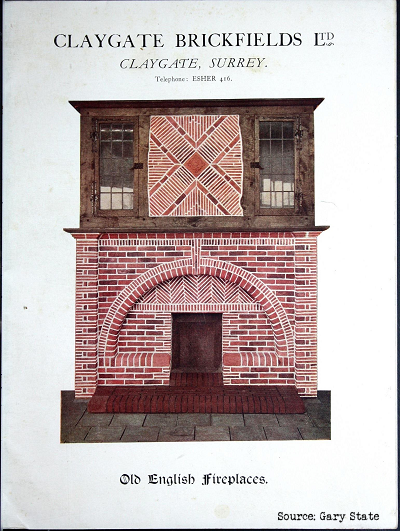

In 1925, the de Bertodanos assigned their lease to Claygate Brickfields Ltd, and in 1930 Mrs. Litchfield-Speer sold the freehold to the de Bertodanos for £2,600. They in turn sold the freehold to Claygate Brickfields for £4,000 in 1934. In 1922 an affiliated company called Claygate Fireplaces Ltd was established, the last chairman of which was Martin de Bertodano.

Claygate Fireplaces rapidly acquired a pre-eminent position in the manufacture of brick fireplaces to the point where its name became synonymous with the product throughout the UK and in some overseas markets. Within a few years the whole output of this brickfield was devoted to the manufacture of high-quality, small bricks (or briquettes) for fireplaces, providing employment for about 100 local people.

There were environmental constraints in the contract: top soil had to be carefully removed and stacked for eventual replacement, and no night working was permitted. Limits on the depth of digging for clay were also prescribed to avoid undermining nearby property and roads.

The Common Road pit had a large working face around 40 feet wide. Where hand-digging was impracticable, a Chaseside mechanical shovel was used to extract the clay. The clay was then piled in mounds and covered with ash, which was later dug into it. The proportion of ash used and the addition of sand was a trade secret and was the major determinant of the colour of the resulting bricks. After de-stoning, grinding and soaking for three days, the clay was processed into blocks and hand-pressed into the 70 odd different shapes required for the various designs of fireplaces made by the firm. After drying, the bricks were fired in round down-draught, coal-fired kilns at a temperature of 950°C for about 70 hours. The process required about one ton of coal per 16,500 bricks — a high fuel consumption by brick industry standards. Finally, the bricks were made up into fireplaces onsite in the slabbing shed.

One of the main entrances to the brickfield was off Common Road, opposite the junction with The Causeway, which later became Glenavon Close. The latter took its name from Glenavon House, once the offices of Claygate Fireplaces. The other main entrance was also off Common Road, not far from the junction with Stevens Lane, and was subsequently developed for housing.

Of the many Claygate families associated with the Common Road brickyard over the years, the aforementioned Welch and de Bertodano families, and the Wellbelove family are probably the best known. The most renowned member of the latter was Jack Wellbelove who started work in this brickyard in 1888 at the age of 12 fetching beer from the local pub, most likely 'The Alma', but possibly 'The Griffin'. His father, nine brothers and nephew also worked in this yard at various times. Jack made the first experimental briquettes for Claygate Fireplaces, and became works manager. Jack Wellbelove finally retired in 1964. The pit and yard were closed shortly thereafter, and after suitable restoration, the land was developed for housing. However, Claygate's association with the manufacture of fireplaces was continued by Galleon-Claygate Ltd which had its headquarters in Tolworth.

References

- Peebles, Malcolm (1983). The Claygate Book. (Millennium edition). Stockbridge: by BAS Printers Ltd. ISBN 0-9508978-0-9.

- Many thanks also for the photos, many supplied by Terry Gale, from the Claygate Local History Facebook group.